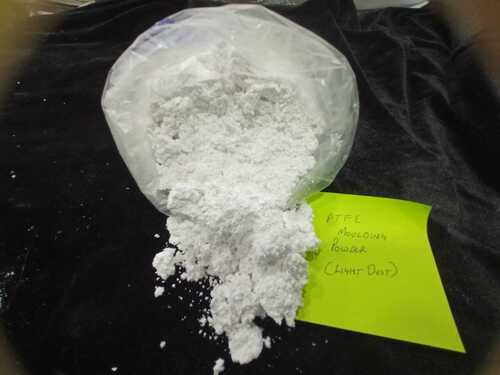

PTFE Moulding Powder Light Dust

350 INR/Kilograms

Product Details:

X

PTFE Moulding Powder Light Dust Price And Quantity

- 350 INR/Kilograms

- 100 Kilograms

- Powder

- White

- negligible

- PTFE Moulding Powder Light Dust

- PTFE (Polytetrafluoroethylene)

- <0.05%

- Store in cool, dry place

- 327C

- High

- >12 months

- 0.450.70 g/cm

- Excellent

- 21 MPa

- 9002-84-0

- Industrial Moulding, Insulation, Gasket and Seal Production

- 25 kg

- Bag

- Industrial Grade

- Fine Light Dust

- 2.15-2.20 g/cm

- 99.9%

PTFE Moulding Powder Light Dust Trade Information

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Delivery Point (DP), Letter of Credit at Sight (Sight L/C)

- 1000 Kilograms Per Day

- 1000 Days

- All India

Product Description

PTFE Moulding Powder Light Dust is a fine powder derived from polytetrafluoroethylene (PTFE) resin through a meticulous manufacturing process. Primarily used in compression molding applications, this powder provides outstanding lubricity, chemical resistance, and non-stick properties. It's commonly utilized in the production of various components like seals, gaskets, and bearings in industries such as automotive, aerospace, and food processing. The benefits of PTFE Moulding Powder Light Dust include its ability to withstand extreme temperatures, excellent electrical insulation properties, and low friction coefficient. Its attributes encompass uniform particle size distribution, ease of molding, and superior performance in demanding environments.

Superior Thermal and Chemical Stability

PTFE Moulding Powder Light Dust maintains its structural integrity and performance under elevated temperatures, with a melting point of 327C. Its exceptional chemical resistance protects against most acids, bases, and solvents, making it a preferred choice for applications that demand longevity and stability.

Precise Industrial Applications

Engineered for industrial moulding, insulation, and the manufacturing of gaskets and seals, the fine powder texture ensures smooth dispersion and reliable end results. Its high dielectric strength and inert properties make it ideal for electrical insulation and precision components.

Long Shelf Life and Safe Storage

With a shelf life exceeding 12 months, this PTFE powder remains effective when stored in cool, dry conditions. The packaging is designed to preserve purity and prevent contamination, ensuring the material's quality remains uncompromised until use.

FAQ's of PTFE Moulding Powder Light Dust:

Q: How should PTFE Moulding Powder Light Dust be stored to maintain its quality?

A: For optimal preservation, keep the powder in a cool, dry place, away from direct sunlight and moisture. Use the original packaging to prevent contamination, as this will help maintain the product's shelf life of over 12 months.Q: What are the main industrial uses of this PTFE moulding powder?

A: This powder is primarily used for industrial moulding, electrical insulation, and fabricating gaskets and seals. Its high purity, fine texture, and thermal stability make it especially effective in environments requiring chemical resistance and electrical performance.Q: When is PTFE Moulding Powder Light Dust preferred over other materials?

A: PTFE Moulding Powder Light Dust is the preferred choice when applications demand high purity, high dielectric strength, excellent thermal stability, and chemical inertness-such as in insulation, gasket production, and specialized industrial moulding processes.Q: Where is this PTFE powder typically applied in industry?

A: It is commonly utilized in manufacturing facilities that produce seals, gaskets, and high-performance insulating components. Its role is especially vital in sectors like electrical, chemical, and processing industries within India and globally.Q: What is the process for using PTFE Moulding Powder Light Dust in manufacturing?

A: Manufacturers typically blend and compress the fine PTFE powder into required shapes using moulds at controlled temperatures and pressures. This process leverages the powder's flow characteristics and thermal stability to achieve precise, high-strength parts.Q: What are the benefits of choosing PTFE Moulding Powder Light Dust?

A: Users benefit from its outstanding purity (99.9%), negligible water absorption, and high tensile strength. These features contribute to highly reliable, durable components, minimizing failures and extending service life in demanding industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free