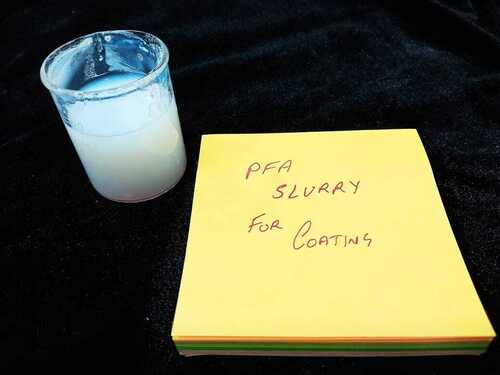

PFA Slurry For Coating

1600 INR/Kilograms

Product Details:

X

PFA Slurry For Coating Price And Quantity

- 10000 Kilograms

- 1600 INR/Kilograms

- Non-toxic

- 5C - 30C

- Water

- Excellent

- Metal, Ceramic, Glass

- 1.30-1.45 g/cm

- 320C 380C

- PFA Slurry For Coating

- < 0.45 micron

- 35-70 cPs

- Milky white liquid

- High

- Heat curing required

- Dip, Spray or Roller

- 60% 2%

- 6-8

- 12 Months in sealed container

- Available in 1L, 5L, 20L containers

PFA Slurry For Coating Trade Information

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque

- 1000 Kilograms Per Day

- 1000 Days

- All India

Product Description

PFA Slurry for Coating is a specialized liquid mixture formed by dispersing polyvinyl alcohol (PVA) micro powder particles in a solvent. This slurry serves as a protective coating in industries like automotive, electronics, and construction. Applied via spraying or dipping, it forms a durable, transparent film, offering exceptional corrosion resistance and barrier properties against moisture and chemicals. Its benefits include excellent adhesion, flexibility, and thermal stability. PFA Slurry enhances surface finish and prolongs product lifespan, making it perfect for coating metal surfaces, electronic components, and architectural structures. Its attributes encompass convenient usage, quick drying, and compatibility with varied substrates.

Exceptional Chemical & Thermal Protection

Engineered for high-demand environments, this PFA Slurry offers outstanding resistance to aggressive chemicals and exceptional thermal stability. Once heat-cured, it forms tough, reliable films that safeguard substrates such as metal, ceramic, and glass from corrosion and thermal degradation, making it perfect for critical industrial applications.

User-Friendly Application Methods

Easy to apply, the PFA Slurry supports multiple coating methods such as dip, spray, or roller, ensuring versatility for a range of production requirements. Its optimal viscosity (35-70 cPs) facilitates consistent coverage, while the water-based carrier ensures safe handling and reduced environmental impact.

Reliable Performance & Storage

This slurry maintains stability for up to 12 months in a sealed container, provided it is stored between 5C and 30C. Available in convenient packaging sizes, it meets varied usage needs, and its non-toxic formulation ensures both operator safety and environmental responsibility.

FAQ's of PFA Slurry For Coating:

Q: How should the PFA Slurry For Coating be applied for best results?

A: For optimal performance, the slurry can be applied using dip, spray, or roller methods onto clean metal, ceramic, or glass surfaces. Ensure uniform coverage and follow with the recommended heat curing process at 320C - 380C to achieve a robust, film-forming layer.Q: What substrates are suitable for coating with this PFA Slurry?

A: This product is specifically formulated for use on metal, ceramic, and glass surfaces, providing an excellent barrier against chemicals and heat, making it ideal for a wide range of industrial applications.Q: When is heat curing necessary in the PFA coating process?

A: Heat curing is essential after application, as it triggers the film formation. Curate the coated item at 320C - 380C, which ensures the chemical and thermal resistance properties fully develop for maximum durability.Q: Where should the PFA Slurry be stored to maximize shelf life?

A: Store the slurry in sealed containers at a temperature between 5C and 30C. Proper storage ensures the product maintains its chemical stability and 12-month shelf life.Q: What benefits does this PFA Slurry offer over conventional coatings?

A: It delivers outstanding chemical resistance, high thermal stability, and a non-toxic profile, making it superior for protective applications on a variety of substrates, particularly in harsh chemical environments.Q: How do I choose the right packaging size for my needs?

A: Evaluate your application volume and frequency to select from available 1L, 5L, or 20L packaging options, allowing flexibility for both small-scale tests and large industrial runs.Q: What is the recommended pH and viscosity for this slurry, and why are they important?

A: The slurry maintains a pH value between 6-8 and viscosity of 35-70 cPs, facilitating easy application and uniform distribution while preserving the coating's integrity during curing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free