White Halar Coating सेवाएं On Vaccum Pump

1800 आईएनआर/Kilograms

उत्पाद विवरण:

X

वैक्यूम पंप पर व्हाइट हैलर कोटिंग सेवाएं मूल्य और मात्रा

- किलोग्राम/किलोग्राम

- किलोग्राम/किलोग्राम

- 1

- On-site and Off-site options available

- Steel, iron, aluminum

- High electrical insulation properties

- Halar ECTFE (Ethylene Chlorotrifluoroethylene)

- Outstanding

- Smooth, glossy

- Minimal, easy to clean

- White Halar Coating सेवाएं On Vacuum Pump

- Superior

- White

- Excellent

- up to 150°C

- RoHS and ISO 9001 Certified

- 80-85 Shore D

- 0.2 mm to 1.5 mm

- Thickness and coverage area as per requirements

- Spray / Dip Application

- High (acids, solvents, bases)

- Vacuum Pump Surface Protection

- Strong to metal substrates

- Typically 5-7 business days

वैक्यूम पंप पर व्हाइट हैलर कोटिंग सेवाएं व्यापार सूचना

- 1000 प्रति दिन

- 1 हफ़्ता

उत्पाद विवरण

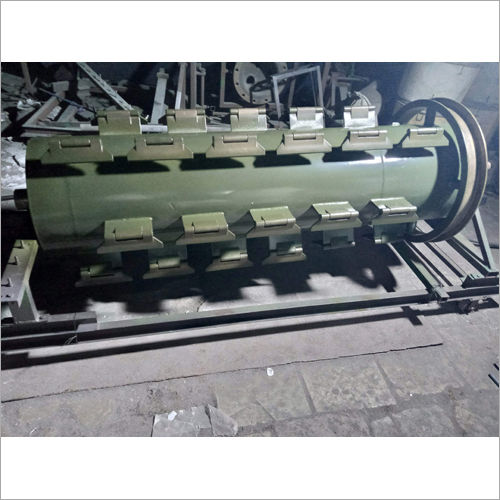

Experience dazzling, unparalleled surface protection for your vacuum pumps with our White Halar Coating सेवाएं. Specially formulated with Halar ECTFE, these laureate coatings combine superior chemical and corrosion resistance, remarkable non-stick properties, and steadfast UV resilience. Each application assures high dielectric strength, brilliant finish, and robust adhesion on steel, iron, and aluminum substrates. Choose from instant checkout and ephemeral special rates, with the flexibility of on-site or off-site service anywhere in India. Certified to RoHS, ISO 9001 standards, our customized solutions offer effortless maintenance and prompt processing in just 5-7 business days.

Exclusive Features & Versatile Applications

Our White Halar Coating सेवाएं for vacuum pumps deliver exceptional protective benefits. Designed for both manufacturer and service provider needs, it offers customized thickness and coverage, smooth glossy finish, and outstanding non-stick performance. Suited for steel, iron, and aluminum, this coating protects against corrosive chemicals and extreme temperatures, making it ideal for demanding industrial applications. Utilize this service for unparalleled pump surface longevity, reduced downtime, and continuous operational efficiency.

Packing, Dispatch & Certifications

Every White Halar Coating project undergoes meticulous packing & dispatch, ensuring coatings are safely handed over or shipped to your location, whether on-site or off-site. We offer sample availability upon request, so customers can evaluate their requirements before full-scale implementation. All services are RoHS and ISO 9001 certified, guaranteeing quality, safety, and environmental responsibility. Your vacuum pumps are protected, documented, and delivered seamlessly from our facility to yours.

Exclusive Features & Versatile Applications

Our White Halar Coating सेवाएं for vacuum pumps deliver exceptional protective benefits. Designed for both manufacturer and service provider needs, it offers customized thickness and coverage, smooth glossy finish, and outstanding non-stick performance. Suited for steel, iron, and aluminum, this coating protects against corrosive chemicals and extreme temperatures, making it ideal for demanding industrial applications. Utilize this service for unparalleled pump surface longevity, reduced downtime, and continuous operational efficiency.

Packing, Dispatch & Certifications

Every White Halar Coating project undergoes meticulous packing & dispatch, ensuring coatings are safely handed over or shipped to your location, whether on-site or off-site. We offer sample availability upon request, so customers can evaluate their requirements before full-scale implementation. All services are RoHS and ISO 9001 certified, guaranteeing quality, safety, and environmental responsibility. Your vacuum pumps are protected, documented, and delivered seamlessly from our facility to yours.

FAQ's of White Halar Coating सेवाएं On Vaccum Pump:

Q: How does the White Halar coating enhance the lifespan of vacuum pumps?

A: The White Halar coating provides high chemical, UV, and corrosion resistance, thereby protecting the vacuum pump from harsh environments and extending its operational lifespan.Q: What is the process for ordering and customizing the White Halar Coating Service?

A: Simply select instant checkout, specify your thickness and coverage area preferences, and choose between on-site or off-site service. Our team will tailor the coating to your requirements and guide you through the process.Q: When can I expect my coated vacuum pump to be ready for dispatch?

A: The typical processing time for coating services is 5-7 business days, after which your vacuum pump will be carefully packed and dispatched to your preferred location.Q: Where can this service be availed in India?

A: White Halar Coating सेवाएं are available across India, with both on-site servicing at your facility and off-site application at our specialized centers.Q: What maintenance is needed after coating application?

A: Minimal maintenance is required. The smooth, non-stick and glossy coated surface is easy to clean, reducing operational hassle and ensuring long-term protection.Q: What substrates are suitable for White Halar Coating सेवाएं?

A: Our coatings adhere strongly to steel, iron, and aluminum vacuum pumps, offering versatile protection across various substrates.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें