Industrial Halar Coating सेवाएं

1800 आईएनआर/Kilograms

उत्पाद विवरण:

X

औद्योगिक हैलर कोटिंग सेवाएं मूल्य और मात्रा

- 1

- किलोग्राम/किलोग्राम

- किलोग्राम/किलोग्राम

- High

- ASTM, ISO Certified

- Within 7–15 Days

- Grit Blasting / Degreasing

- 200 kV/cm

- Thermal Curing

- Excellent

- 150°C

- Yes

औद्योगिक हैलर कोटिंग सेवाएं व्यापार सूचना

- 1000 प्रति दिन

- 1 हफ़्ता

उत्पाद विवरण

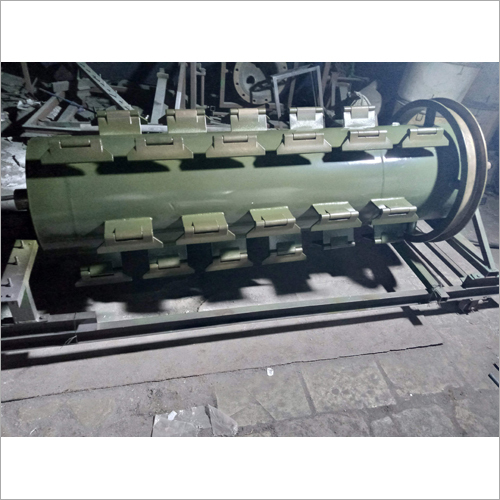

Ending Soon: Secure our Stellar Industrial Halar Coating सेवाएंcrafted for those who recognize the value of rarefied quality. In demand across Indias top industries, our Halar coatings boast a paragon dielectric strength of 200 kV/cm, exceptional weather resistance, and high adhesion to substrates. With a maximum operating temperature of 150C and non-stick properties, our thermal curing guarantees lasting performance. Grit blasting and degreasing methods ensure flawless pre-treatment. Order today and experience ASTM and ISO certified excellence from a trusted manufacturer, service provider, and supplier. Lead time is within 715 days!

Targeted Application & Advanced Methods

Industrial Halar Coating सेवाएं are suitable for diverse environments including chemical processing plants, pharmaceuticals, and electronics sectors. We expertly apply coatings via fluidized bed or spray systems, on-site or off-site, based on project needs. With high compatibility for pipes, tanks, and equipment, our services ensure optimal coverage and protection. Our application process is tailored for maximum efficiency, with seamless integration tailored to the area of applicationbe it new installations or maintenance refurbishments.

Delivery, Pricing & Sample Policies

With a standard lead time of 715 days, our Industrial Halar Coating सेवाएं are available for dispatch from major Indian FOB ports. We are transparent about our list price and provide detailed charge structures at the time of order. Delivery is prompt and traceable. For customer assurance, our sample policy offers on-request samples with nominal charges, allowing you to evaluate our service quality firsthand before committing to larger volumes.

Targeted Application & Advanced Methods

Industrial Halar Coating सेवाएं are suitable for diverse environments including chemical processing plants, pharmaceuticals, and electronics sectors. We expertly apply coatings via fluidized bed or spray systems, on-site or off-site, based on project needs. With high compatibility for pipes, tanks, and equipment, our services ensure optimal coverage and protection. Our application process is tailored for maximum efficiency, with seamless integration tailored to the area of applicationbe it new installations or maintenance refurbishments.

Delivery, Pricing & Sample Policies

With a standard lead time of 715 days, our Industrial Halar Coating सेवाएं are available for dispatch from major Indian FOB ports. We are transparent about our list price and provide detailed charge structures at the time of order. Delivery is prompt and traceable. For customer assurance, our sample policy offers on-request samples with nominal charges, allowing you to evaluate our service quality firsthand before committing to larger volumes.

FAQs of Industrial Halar Coating सेवाएं:

Q: How is the Industrial Halar Coating applied to different substrates?

A: Our application process involves either fluidized bed or spray method, chosen based on the substrate and project requirements. We begin with grit blasting or degreasing for surface preparation, ensuring maximum adhesion and effectiveness of the coating.Q: What benefits do the non-stick properties of Halar coating provide?

A: The non-stick characteristics minimize buildup and simplify cleaning, making equipment more efficient and reducing maintenance downtime. This feature is particularly beneficial in sectors handling sticky or corrosive materials.Q: When can customers expect delivery after placing an order?

A: Delivery is typically completed within 7 to 15 days from order confirmation, depending on project scale and location. This prompt lead time helps keep your operations running smoothly.Q: Where can these coating services be applied?

A: Our Halar coatings are ideal for industrial settings including chemical plants, pharmaceutical units, electronics manufacturing, and any application requiring high dielectric strength and weather resistance.Q: What is the process for requesting a sample before placing a large order?

A: Samples are available upon request as part of our sample policy, usually with a nominal charge. This allows customers to assess the quality and suitability of the coating before proceeding with full-scale application.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें